The Farnham Craft Trail offers visitors a rare chance to step inside the studios and workshops of local craftspeople. Across the town and surrounding area, you can meet furniture makers, ceramicists, weavers, glass artists and more, each opening their doors to show how their work comes to life. It is a wonderful opportunity to see craftsmanship up close and to appreciate the skill, creativity and dedication behind handmade work.

Explore our Gallery, showcasing work by current and former students and our maker-trainers. Enjoy live demonstrations in the main workshop, offering insight into the skills we teach and use, including steam bending, marquetry, woodturning, hand work at the bench, upholstery, and weaving.

Our Open Workshop will give visitors an insight into the atmosphere of our workshop and the processes that shape fine furniture making. You will be able to meet our tutors and students, watch demonstrations, and see projects in progress. Whether you are interested in learning traditional woodworking skills yourself or simply enjoy seeing how beautiful pieces are made, our Open Studio offers a warm and inspiring welcome.

We are proud to be part of Farnham’s thriving community of makers and look forward to opening our doors during the Craft Trail. We hope you will join us to experience the craft, care and creativity that lie at the heart of our school.

There will be free parking, coffee and tea. Here some information on how to find us:

Farnham School of Furniture Making | Aidan McEvoy Fine Furniture, Willey Park Farm, Alton Road, Farnham, GU10 5EP.What3Word Link here.

If you are travelling west on the A31 (from Farnham towards Alton), make a U-turn at the Farnham House Hotel sign so you are heading back east towards Farnham. The Farnham School of Furniture sign is visible from the A31 on the left-hand side. Turn left into the farm drive.

Map can also be accessed via the Brochure on the Farnham Maltings Website here.

'Hommage to Nature (2nd Ballad)' by Jarrad Belton, one of our tutors.

On Saturday 26 and Sunday 27 October, a Farnham-based woodworking school and bespoke furniture makers Aidan McEvoy Fine Furniture, will be opening their doors to the public for the first time to celebrate the Farnham Craft Trail.

Visitors to the traditional hand cut timber framed buildings, based in Willey Park Farm on Alton Road, Farnham, will be treated to live demonstrations from woodworking experts including woodturning, hand cut dovetail joints and marquetry (creating patterns and designs using layers of materials such as hardwood or shell). Additionally, visitors can learn more about the types of wood used in fine furniture making, how the School sources wood sustainably and the journey it takes from woodland to workshop.

Tea and coffee will be available throughout the weekend as well as access to a gallery of furniture pieces made by past and present students. A competition testing visitors knowledge of native wood species will also be running over the weekend. Excitingly, the first 10 visitors over the weekend will be given their very own native Hardwood sapling to take home and plant.

Aidan McEvoy Fine Furniture has been producing bespoke furniture for over 19 years, including pieces for Queen Elizabeth II. Aidan’s unique vision and creativity extends to the school, ensuring that all teachers are also current furniture makers who share his passion and desire to pass on the craft. Woodworking and furniture making courses are available for all abilities and during the Craft Trail weekend a number of popular courses will be available to book with a 10 per cent discount.

To find out more about Aidan McEvoy Fine Furniture or to book a separate visit, please contact: info@amfinefurniture.co.uk or visit our Instagram.

Julia Main talks about training with AM Fine Furniture and her ambition to set up a business making wooden toys and furniture for children

Q. Tell us a little bit about you and your background…

About five years ago, my partner and I relocated to Canada with our one-year-old son. The initial plan was to go travelling but when we found out I was pregnant with our second child, we decided to settle for a few years in a little place called Revelstoke, east of Vancouver. In early 2022, we came back to England to sort out a driving licence for a 40-foot school bus we had converted into a motorhome, but it was just as the country went into lockdown. We stayed with family for several months but because the borders stayed closed for so long and our eldest was due to start school, we decided to move back to England.

We now have three children and with one in school and the other two in nursery, I was keen to get back to work. But the big question was, what shall I do? I knew I didn’t want to return to hospitality, which I’d been doing before the kids, so I looked at retraining in something new and creative.

Q. What made you decide to do a course in fine furniture making?

Having the kids has made me really aware of how many toys are made of plastic, which in a year or two are broken or simply thrown out and sent to a landfill, where they take hundreds of years to break down. It just doesn’t make sense to me and isn’t how I think we should be living.

I’ve always liked the wooden toys made by companies like Grimm’s and Ostheimer, which we buy for the kids. They are slightly more expensive, but they fall under the Waldorf style of toys, which are natural and more sustainable, and the general principle is that your children don’t need tonnes of toys, and therefore quality is better than quantity. However, there are times when I still want to get my hands on a particular type of toy, but it’s not available in wood. So, I started thinking, wouldn’t it be great to design, make and sell these sorts of toys myself?

Q. Had you done any woodwork prior to your training?

I had made the kids a couple of climbing arches and climbing ramps, from watching YouTube videos. And when we were converting the school bus into a motorhome in Canada, there was a lot of carpentry involved – all the cladding inside was made of wood and we built bunk beds, wooden storage boxes and tables, and so on. But it wasn’t until I started my course with Aidan that I realised this was a ‘rough’ type of woodworking and very different to fine furniture making!

Q. Why did you choose to train with AM Fine Furniture?

I looked at lots of different types of training, from university degrees to college courses and apprenticeships, but most of these were too long, too expensive or didn’t focus on the woodworking skills I wanted to learn. As we have three kids, it was important to me that the course was nearby and wouldn’t place too much burden on my partner, who would be taking over the childminding while I trained. I found Aidan’s course online and it was ideal – it was a 45-minute drive away, the right length, at a workable time of day and the right price. I also thought that training with someone in my area would be an advantage, as Aidan would have lots of knowledge about making fine furniture in Surrey and where to source the best local wood, et cetera.

Q. Tell us a bit about the course and the workshop…

It was a six-week course that ran from 9am to 5pm, Monday to Friday, but the workshop was open from 8am until 7pm, for those who wanted to practise what they’d learnt or to catch up, if they were slightly behind. Staying late wasn’t an option for me because that was family time that I didn’t want to give up, but I managed to just about get everything done by the end of the course, even if it was a bit intense at times!

There were only seven of us on the course – me, one other woman and five men, and we all got on very well. And the location of the workshop is amazing. I loved pulling up in my car and being amongst the horses and farm dogs and looking out of the window at the Farnham countryside.

Q. What had you made by the end of the course?

The project we were working on was a small side table made from English walnut, with a sycamore drawer. There’s a nice contrast between these two woods that you can clearly see in the dovetail joints, when you open the drawer.

Q. What was it like, learning to use all the different tools?

Some of them I hadn’t even heard of before I started the course and when they arrived in the post, I’d open the package and think, what the hell is this? But by the end of the six weeks, I was confident in handling them all and I was amazed by the great finish you can achieve from using just hand tools. I think that must be a testament to Aidan’s teaching, because everyone’s table looked amazing, regardless of where they were on their woodworking journey. Aidan was a real stickler for getting something right before moving on to the next task, otherwise that little thing you skipped over would come back and bite you further down the line.

Q. What part of the course did you enjoy the most?

I enjoyed everything about it, but I particularly liked the fact that we were learning something new every day, which kept it really engaging. I also liked the demographics of the group. Everyone was mature, and a few of us were local and looking to set up a business in woodworking, so we all had quite a lot in common.

Q. What aspect of this new craft have you found the most challenging?

Cutting the joints. Whether it’s a dovetail or mortise and tenon joint, they have to be perfect or they don’t fit together properly. Spending so much time on something and then having to start again is very hard, but it is worth it in the end. For example, the first dovetails I made had huge gaps and because I thought I had made them perfectly, I wondered how on earth I was going to get it right, but after I’d done three or four, they were suddenly starting to look so much better and the end result was beautiful. It really is so rewarding, seeing your skills progress.

Q. Woodworking skills aside, what else did you learn by doing this course?

For those of us looking to go into business, we talked about the need to design and make things that are different to what’s already available and placing yourself in a market that you can compete in. For example, given the level of time and effort that goes into fine furniture making, it’s unlikely that you’d be able to compete with a garden furniture set that’s made in China and available in most garden centres. Instead, you need to place emphasis on your products being local, sustainable, hand-made, and a potential heirloom.

On a personal level, it made me appreciate the kids more but it also made me realise the importance of having a good balance between work and family life. I missed the kids, but it was so nice to walk out of the door, leave all the ‘mummy stuff’ behind and do something that was just for me. It was also refreshing to be learning a new skill again.

Q. Was it difficult juggling being a mum and doing a six-week course?

My partner and I were lucky enough to form a good routine. I’d get the kids fed and ready in the morning and then my partner would take over at 8.15am, after he’d already worked from home for several hours. He’d also be able to pick up his work again, in between the school and nursery run, and taking the kids to different activities. I’d then get back home at about 6pm and the kids would descend on me, often in tears – even though I’d seen then through the window just moments before, eating their supper quite happily! In fairness, I think it was quite hard for them, because I have always been there, since they were born.

Q. What’s next for Julia?

I’m hoping Aidan will put on a machining course in the future, as I think those extra skills would be useful for the line of work I’m hoping to go into. Otherwise, in the short-term, the plan is to set myself up in a corner of my parents’ workshop and then start working on three or four designs I’d like to make, to see which is the most feasible. Until all the kids are at school, full-time, I’ll probably spend three days a week focusing on my woodwork, because they’re only little for a short time and I don’t want to miss it. In the longer term, if it looks like the business is financially viable, then we’ll probably build a workshop in our own garden and progress from there.

One thing that really appeals to me is the idea of creating the ‘whole package’. I think I will really enjoy not just designing and making wooden toys and furniture for children, but also the marketing and photography needed to promote these products and setting up a shop.

Q. What advice would you offer someone looking to do the same course?

Do it. It can be overwhelming, thinking about training in something new, especially if the aim is to set up a new business at the end of it. By going on this course, you have the support of an expert in his craft, and you can also share your concerns and learn from the other people you’re training with. It’s much better and less stressful than trying to teach yourself from YouTube videos and forums, which is how I started!

Find out more about AM Fine Furniture's Six Week Furniture Making Course

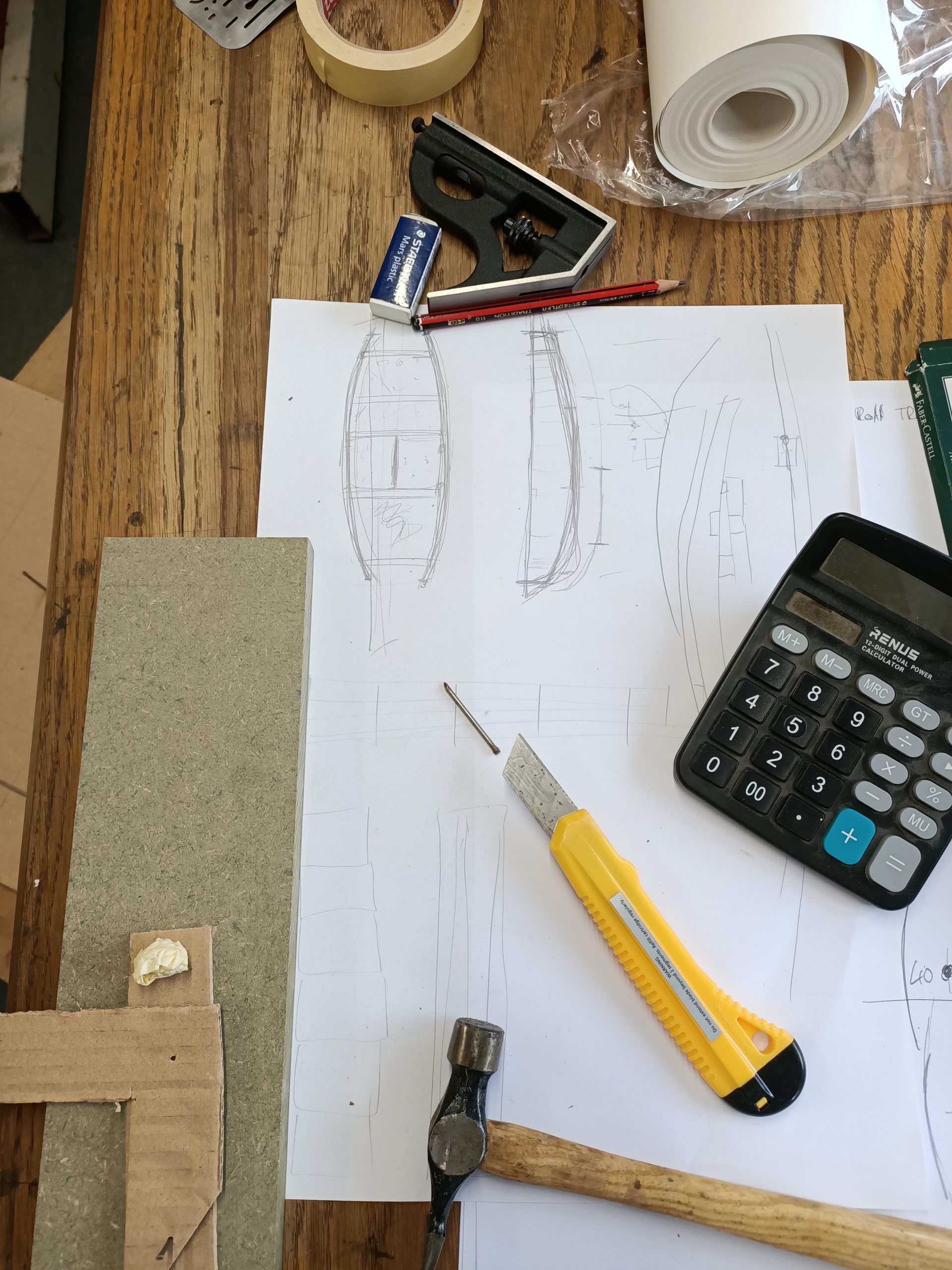

One of our 12-month professional furniture making students is currently working on the course’s Laminating & Veneering module. The project for this module is a curved wall cabinet.

This wall-mounted cabinet has a number of challenging aspects which develops the student’s knowledge in mould-making, templates, and jig making, as well as laminate and hand-cut veneer preparation.

One of our 12-month professional furniture making students is currently working on the course’s Laminating & Veneering module. The project for this module is a curved wall cabinet.

This wall-mounted cabinet has a number of challenging aspects which develops the student’s knowledge in mould-making, templates, and jig making, as well as laminate and hand-cut veneer preparation.

This cabinet is particularly challenging as it involves the inset-hanging of a door, with a double curvature front. This can be a real head-scratcher when planning the choice of ironmongery.

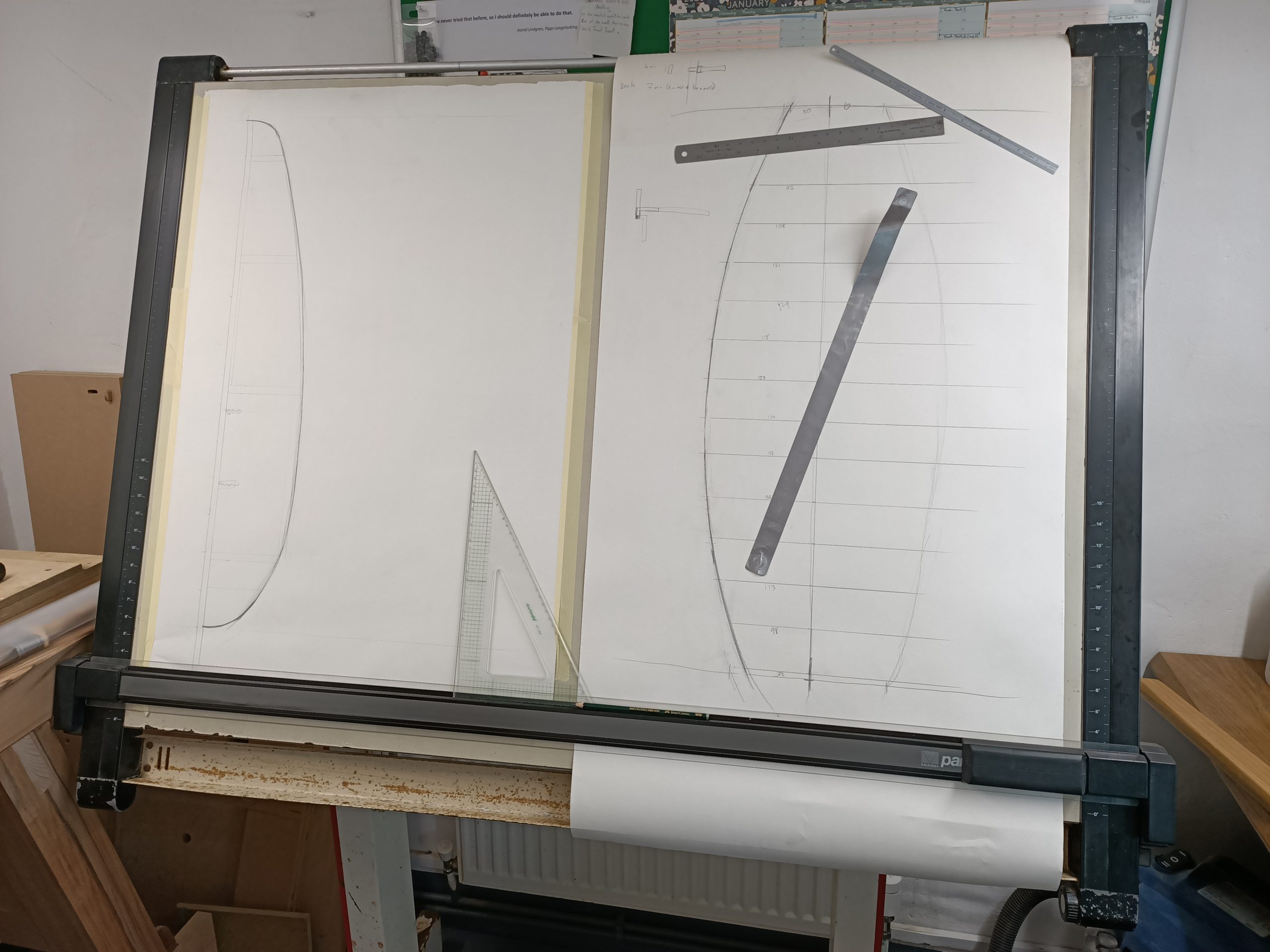

She started by hand-drafting the whole project on a drawing board. Then transferring this information onto working rods. These were used to make templates to cut the moulds.

This cabinet is particularly challenging as it involves the inset-hanging of a door, with a double curvature front. This can be a real head-scratcher when planning the choice of ironmongery.

She started by hand-drafting the whole project on a drawing board. Then transferring this information onto working rods. These were used to make templates to cut the moulds.

She then used these moulds to first press the hand-cut laminations of English Walnut in the vacuum bag press.

She then used these moulds to first press the hand-cut laminations of English Walnut in the vacuum bag press.

She then made another set of templates, which assisted with shaping the side panels.

She then made another set of templates, which assisted with shaping the side panels.

One of the more challenging processes in this project was figuring out how to cut the housing joint into the curved sides that the shelves would fit into. As their ends had to be perpendicular to the centre line of the cabinet. She achieved this by making the large jig as pictured.

One of the more challenging processes in this project was figuring out how to cut the housing joint into the curved sides that the shelves would fit into. As their ends had to be perpendicular to the centre line of the cabinet. She achieved this by making the large jig as pictured.

After spokeshaving the curved side panels and dry-fitting, next steps will be preparing and installing the back panel, made from exceptionally beautiful spalted Walnut.

After spokeshaving the curved side panels and dry-fitting, next steps will be preparing and installing the back panel, made from exceptionally beautiful spalted Walnut.

During the summer, we made new benches for our summer pop-up Workshop, which have proven to be quite popular. As we have now moved back into the main Workshop, we’re offering three of these summer Workbenches for sale.

Each Woodworking Workbench comes with bench dogs, shooting board, and bench hook, so that you can start woodworking immediately.

Please contact us if you would like further information.

During the summer, we made new benches for our summer pop-up Workshop, which have proven to be quite popular. As we have now moved back into the main Workshop, we’re offering three of these summer Workbenches for sale.

Each Woodworking Workbench comes with bench dogs, shooting board, and bench hook, so that you can start woodworking immediately.

Please contact us if you would like further information.